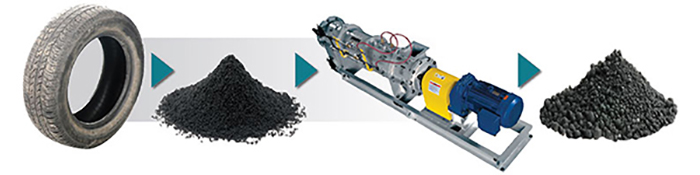

rCB Pelletizing Transforms ELTs into Sustainable Solutions

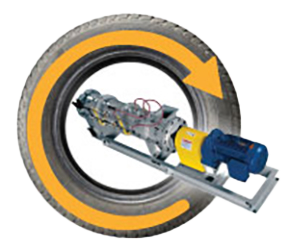

Tire pyrolysis companies and tire recyclers worldwide rely on Mars Mineral pin mixers' continuous, low-maintenance operation to convert rCB into valuable pellets at the optimal size and hardness most coveted by end-users. Pelletizing takes on the environmental challenge caused by the annual disposal of over one billion end-of-life tires (ELTs) and turns them into a sustainable, circular economy solution.

Achieve Your Revenue Potential

For the past 50+ years, Mars Mineral has manufactured advanced agitation agglomeration or pelletization equipment and offered comprehensive applications experience in:

Lab & Pilot-Scale Testing

Process Consultation

Equipment Rental

Onsite Technical Consultations & Services